Contact an expert

Please fill out the form to contact the expert

Success

Our expert will contact you shortly

ESP Systems

- Pumps

- Gas Handling

- Motor Seals

- Downhole Motors

Levare compression pumps cover a wide range of flow rates and are very tolerant to higher thrust loads and abundant solids in the produced fluids.

Unlike floater pumps, compression pumps are better able to manage varying thrust loads in rapidly changing flow conditions as is often experienced with gas slugging. When a compression pump begins to operate in down thrust, the force is transferred and managed at the thrust bearing in the motor seal. Absorbing this down thrust force in the clean oil environment of the seal section helps extend pump run life.

Levare Packet pump is better able to withstand prolonged down thrust and abrasive production typically experienced by ESPs in unconventional well applications. The Packet pump is constructed such that as mechanical wear progresses, stage impellers will lock together in groups (configurable packets) so as to limit the axial movement of the packet along the shaft. Down thrust is then dynamically managed through a tungsten carbide (T) bearing in the diffuser at the base of each packet.

Benefits

Increased production even in challenging environments

Longer ESP run life improves ROI

Wider pump operating range helps reduce intervention costs

Available stage types

flow rates

Available stage materials

to wear and corrosion

Levare gas handling devices allow continuous operation of ESP systems in gassy applications, increase and improve ESP production by conditioning the gas-liquid mixture and eliminating gas locks to further reduce the tendency for underload shutdowns due to gas interference in the pump.

The versatile portfolio of Levare gas handling devices provide trouble-free ESP system operation in well conditions with free gas content up to 90% at the pump intake when Levare gas separator is installed together with Vapro gas handler.

Levare gas separators provide efficient mechanical separation of free gas from the produced mixture. They are available in 272, 338, 400, and 538 series and cover virtually every production rate delivered by the extended product line of Levare pumps. Gas separators feature abrasion-resistant design and can be trusted by conventional and unconventional oil producers.

| Gas separator type | Max flow rate of the connected pump @ 60 Hz | Max free gas at pump intake |

|---|---|---|

| ESP 338 RGS | 1,500 bpd | up to 65% |

| ESP B 400 VGS CW 3000 | 3,000 bpd | up to 75% |

| ESP B 400 VGS CW 5800 | 5,800 bpd | up to 75% |

| ESP B 538 VGS CW 9000 | 9,000 bpd | up to 75% |

The Levare Vapro gas handler efficiently handles higher percentages of free gas in gassy wells, allowing continuous operation of ESP systems in extreme gas conditions and reducing the tendency for underload shutdowns due to gas interference in the pump.

The Vapro multiphase pump incorporates an axial-flow impeller optimized to reduce gas bubble size and create a more homogenous flow regime at a higher GLR, in the pump. This mixture of gas and liquid behaves more like a single-phase fluid helping to stabilize the flow moving into the primary pump.

When the Vapro pump is run in combination with the Levare Vortex gas separator, ESP production with GVF up to 90% is achievable.

| Gas separator type | Max flow rate of the connected pump @ 60 Hz | Max free gas at pump intake |

|---|---|---|

| 400 Vapro 2000 | 717 – 2,038 bpd | up to 70% |

| 400 Vapro 3500 | 832 – 3,782 bpd | up to 70% |

| 538 Vapro 2600 | 400 – 2,300 bpd | up to 65% |

| 538 Vapro 4400 | 1,600 – 4,400 bpd | up to 65% |

| 538 Vapro 12500 | 4,000 – 13,000 bpd | up to 65% |

Incorporating state-of-the-art technology, materials, and operational experience, Levare motor seals provide premium motor protection to extend run life in the most demanding applications.

Featuring a patented thrust chamber designed for optimal oil circulation to cool and stabilize the bearings at high loads, Levare seals provide reliable motor protection in harsh well conditions. Robust metal bellows motor seals are designed for high-temperature applications.

Configurable design in an elastomeric bag-type, metal bellow or a labyrinth-style chambers

Sand handling technology in head enables effective operation in abrasive wells

High load bi-directional thrust bearing that handles deep-set compression, packet and floater pumps

Steel, bronze or tungsten carbide bearing sets positioned along the shaft for added stability and high brake horsepower applications

Levare motor seals are available in either an elastomeric bag-type, metal bellow or labyrinth-style chambers, and they can be configured in a variety of tandem combinations to provide motor protection for any operational need.

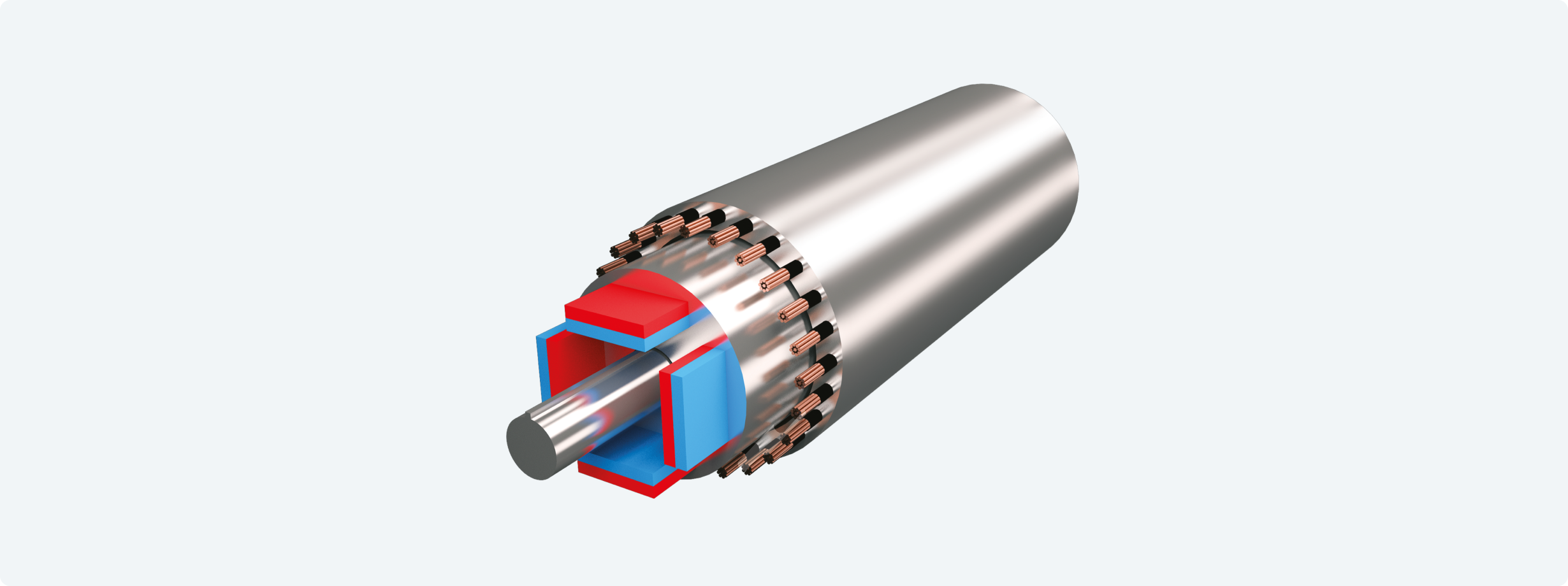

Levare offers complete range of Induction and Permanent Magnet Motors for electric submersible, progressing cavity and plunger pumps. All motors come in wide range of specifications in order to satisfy diverse needs.

Levare offers in-house manufacturing to the highest standards and consistency along with the quality nickel copper alloy-trim fasteners, robust rotor bearings and closed slot design.

- Induction Motor

- Permanent Magnet Motor

The two-pole, three-phase induction motor continues to be an ESP industry workhorse. Levare induction motors are designed for maximum reliability and efficiency even under the most demanding operating environments. We offer a complete range of induction motors for all ESP applications including.

Multiple sizes and configurations, variable horsepower

and voltage ratings

Motor rating temperature of 200°C (392°F) for conventional applications and up to 300°C for SAGD and geothermal wells

Operating speed from 35 Hz to 75 Hz

High-strength shaft materials and maximum torque capacity

Stainless steel materials or MONEL coating for corrosive environment

Motor Series

Levare was the first company in the world to commercialize the permanent magnet motor (PMM) for ESP downhole applications in 2006. Since then, Levare has deployed more than 22,000 PMMs around the world serving a variety of ESP and PCP applications.

Permanent magnets – specially engineered and embedded in the rotor – create a constant rotor magnetic field. No electrical power is consumed in generating the rotor magnetic field. As a result, the PMM rotor experiences little to no electrical losses, is more efficient, and has higher horsepower density. This translates to a synchronous PMM with a wide operating range that consumes less energy, generates less heat and is shorter in length than an induction motor of the same rating.

ESP Motor Series

PCP Motor Series

Having pioneered the technology, today Levare has the largest proven PMM portfolio and experience. PMMs have shown to improve ESP operations by:

Standard Duty

Standard construction floater and compression pumps using:

- carbon steel heads and bases, housings, and compression nut

- stainless steel key, half rings, retaining rings, and MONEL K-500 fasteners

Harsh Duty

Floater and compression pumps fitted with TC bearings at 1.1 ft (0.35 m) interval spacing and using:

- stainless steel or MONEL K-500 coated carbon steel heads and bases

- stainless steel keys and half rings

- stainless steel or INCONEL retaining rings and MONEL K-500 fasteners

Floater and compression pumps exhibit similar solids handling ability, however, compression pumps are recommended for use in variable flow and higher GOR conditions

The option to use Packet pumps fitted with TC bearings at 1.1 ft (0.35 m) interval spacing and using

- stainless steel heads and bases

- keys and rings (INCONEL retaining rings optional)

- stainless steel or MONEL K-500 coated carbon steel housing

- MONEL K-500 fasteners

Extreme Duty

Compression pumps fitted with TC bearings in every diffuser and using:

- stainless steel heads, bases, and housing

- MONEL K-500 compression nut, keys, half rings, and fasteners

- INCONEL retaining rings

The option to use Packet pumps fitted with TC bearings every third stage and using:

- stainless steel heads and bases

- keys and rings (INCONEL retaining rings optional)

- stainless steel or MONEL K-500 coated carbon steel housing

- MONEL K-500 fasteners

The option of metal bellows applications for SAGD and geothermal applications (up to 300°C)