Contact an expert

Please fill out the form to contact the expert

Success

Our expert will contact you shortly

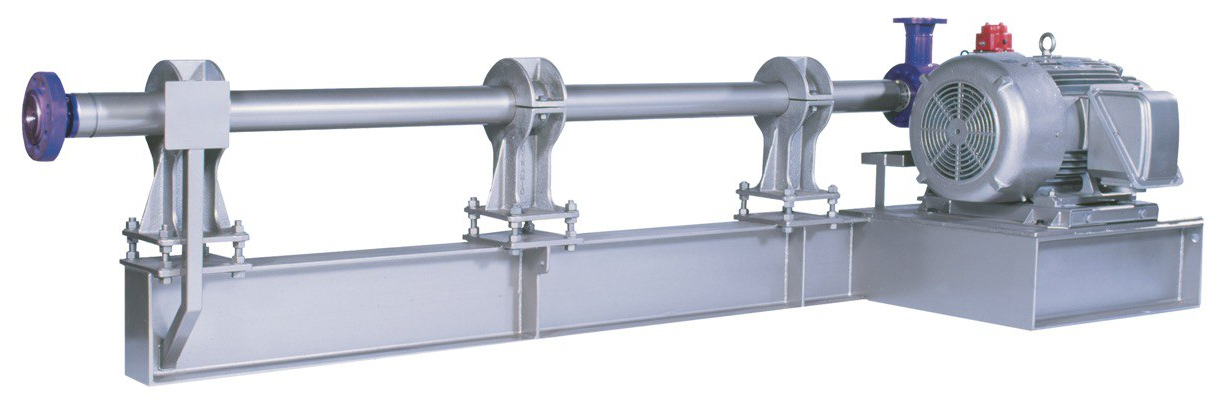

Horizontal Pump Systems

The industry leader in horizontal pumping systems (HPS), Levare offers fit-for-purpose HPS technology, products, and services to minimize costs and maximize return on investment. We provide a cost-effective, low-maintenance, multistage horizontal centrifugal pump solution for surface pumping applications requiring fluid injection, lift, and transfer.

Our engineers design and fabricate innovative horizontal surface pumping systems to provide specific solutions to a wide range of fluid-movement applications. We offer greater flexibility for your pumping needs and take added measures to provide:

24-hour technical field service

Maintenance programs for all HPS units and components

Maximized use of surplus inventory

Site-ready delivery of all units

Our horizontal pumping system design is environmentally safe, low vibration, and engineered in accordance with your requirements for use as

Injection pumps in the formation pressure maintenance system

Booster pumps

Jockey pumps in the pipeline

Hydraulic drives

Utilization of formation water

Drainage

Transferring industrial liquids

Transferring CO₂ and liquefied gas

Most rigid designed skid in the industry

All skids are engineered and custom built as per application

All lifting points are built into the skid

Design options

Low Pro (up to 100 HP)

Single Beam (up to 300 HP)

Dual Beam (up to 2,000 HP)

100-1,500 hp motors 2-pole electric 3,600 rpm

Options include: TEFC, WPII, sleeve or ball bearing

Special features: bearing winding RTDs and space heaters

Eliminates vibration

Zero maintenance required

Easy removal of spacer for service of equipment

Modular load design

Longest industry run lives

Back pull out for quick seal changes

Minimal maintenance required

Standard single bellow seals type 2

Available in single and dual cartridge seals

Flush plans as per customer application/request

Solid constructed machined intake – standard 316 SS – 150 – 900 ANSI RF

Alternative materials and class sizes available for pressure up to 3,000 psi

Accommodates all seal applications

| Standard flow offering of | 1,050-46,000 bpd (170-7,350 m³/d) |

|---|---|

| Pump series range | 4’’ - 9.50’’ |

| Standard tungsten carbide bearing and sleeves for abrasion wear | |

| Material | standard Type 1 Ni-Resist |

| Other | alternate materials available upon request |

Engineered for reliability, modularity, and quick component replacement, our pump has a lower life cycle cost due to minimized downtime and low maintenance requirement. The result is a reliable, versatile, and innovative pumping system.

The Levare HPS is a multistage horizontal centrifugal pump featuring.

environment

or thrust chamber

option

double casing

Since the 1990s, it has been a reliable, cost-effective, and versatile alternative to traditional high-pressure pumps. From simple water injection and disposal to more complex refinery, NGL, and offshore service, the HPS can deliver up to 2,000 hp in a single unit.

Our patented Low Pro Mini HPS is the ideal solution for small applications. It’s an economic, maintenance-free, thrust chamber-less pump that can be delivered quickly to your location.

The motor is direct coupled to the pump, and the standard instrumentation is mounted on the skid including suction and discharge transmitters and vibration transmitter. The pump thrust load is carried by the motor bearing.

Standard 316 SS from 300-2500 ANSI RF or RTJ

Other: alternate materials available upon request

Standard offering is the intake & discharge pressure transmitters as well as vibration transmitters

All units come with CSA/UL certification available in Class 1 Div 2 and explosion proof