Contact an expert

Please fill out the form to contact the expert

Success

Our expert will contact you shortly

PMM PCP Systems

Download bookletFor well conditions that challenge conventional electrical submersible pump (ESP) or progressing cavity pump (PCP) systems, Levare offers a cost-effective alternative to increase well productivity and system run life.

Submersible PCP artificial lift systems are optimal where traditional rod-driven systems are limited by depth or where deviated or crooked wells have caused premature rod/tubing wear because submersible PCP systems have no rods. They deliver the best performance in horizontal and deviated wells; low-volume wells with unstable inflow; wells with viscous, abrasive fluids; wells with a high gas-oil ratio (GOR); and wells with scale and high amounts of asphaltenes.

Levare extensive global manufacturing capacity includes state-of-the-art plants that produce all major components of ESP, HPS, and PCP artificial lift systems. All facilities use advanced machining, assembly, and testing technologies to ensure production efficiency and the highest level of product quality.

Applications

Deviated and horizontal wells

Low flow rate and unstable inflow wells

Heavy oil and viscous oil wells

Wells producing with higher solids volume or scale

High lift system adaptability to variable conditions

Features

Low-speed, high-torque PMM

- Speed range of 100-1,500 rpm

- Torque up to 1,670 lb-ft

Independent thrust chamber to carry and equalize developed thrust load

Flush valve to reduce and smoothen starting torque impact on motor and system

Downhole monitoring sensor

Surface variable speed drive

Handles up to 50% free gas

Handles up to 0.6 g/l solids

No fluid emulsification

- Pumps

- Motors

Our submersible PCP applications use highly efficient progressing cavity pumps and are designed for wells where traditional rod-driven systems are limited by depth and rod and tubing wear. They’re also practical for low-volume wells where conventional ESPs have limitations such as low efficiency, plugging, and erosional wear.

By extending PCP application range, the system allows operators to take advantage of the efficiency and solids-handling ability of a PCP pump in wells where this technology was not an option due to wellbore geometry.

PCP Specifications @ 500 rpm

| Pump series |

Flow range,

120-750 rpm

|

Max. head | Max. pump power consumption | Max. recommended motor power |

|---|---|---|---|---|

| 362 |

9 – 283 bpd |

8,203 ft |

20.1 hp |

24 hp |

| 406 |

18 – 1,182 bpd |

8,203 ft |

35.8 hp |

48 hp |

All Levare PMM-PCP systems can be equipped with Downhole sensors

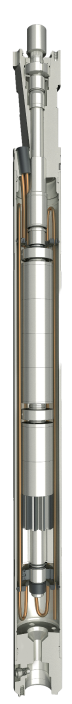

The Levare PMM-PCP artificial lift system is a permanent-magnet-motor-driven electric submersible progressing cavity pump (ESPCP) that provides the benefits of a PCP without the safety and abrasion risks associated with a steel rod string to surface.

The low-speed, 10-pole PMM employs a rotor with permanent magnets made of sintered hard-magnetic materials. Magnets produce the rotor flux and so require less power for field generation. Increased efficiency and synchronous operation translate into reduced electrical loss, lower operating current, and less heat generation.

The Levare PMM-PCP system makes it possible to produce deviated wells at lower rates and reduced power consumption than historically deemed feasible with ESPs.

Low-speed PMM Specifications @ 500 rpm

| Motor series | Max. power | V | A | Max. efficiency | Power factor | Max. torque |

|---|---|---|---|---|---|---|

| 456 |

60 hp |

157-1,063 | 34 | 79% | 0.96 | 620 lb-ft |

| 562 |

159 hp |

247-2,343 | 36.5 | 83% | 0.96 | 1.670 lb-ft |

All Levare PMM-PCP systems can be equipped with Downhole sensors

Operating Conditions

| Pump depth * | 8,202 ft (2,500 m) |

|---|---|

| Water cut at pump intake | up to 99% |

| Fluid specific gravity | up to 1.4 |

| Produced water pH * | 6.0...8.5 |

| Fluid viscosity * | up to 1,000 cP |

| Solids content | up to 1 g/l |

| Mohs’ hardness number | up to 5 |

| Free gas content at pump intake | up to 50% |

| H2S content | up to 0.125% |

| Fluid temperature * | 80°С – 120°С |